Material of rings

Materials for Rings and Rolling Elements

Usually the rolling element of the slewing ring chooses the integral quenched carbon chrome bearing steel, GCr15 or GCr15SiMn steel. The ring chooses the surface quenched steel; 50Mn steel is usually chosen for the manufacture if the users have no special requirement; in some special circumstances, the surface quenched steel in other designations may be used according to the customers specific use conditions, such as 42CrMo and 5CrMnMo etc.

Materials for cages

The structure of slewing ring cage has the integral type, sectional type and isolated type etc. The integral and the sectional types choose the 20# steel or ZL102 cast aluminum alloy. The isolated type chooses the polyamide 1010 resin and ZL102 cast aluminum alloy etc. In recent years with the constant development of material industry, nylon GRPA66.25 is also promoted and applied in the design of sectional type cage.

Materials for seal rings

The seal ring of slewing ring chooses the oilproof NBR for manufacture.

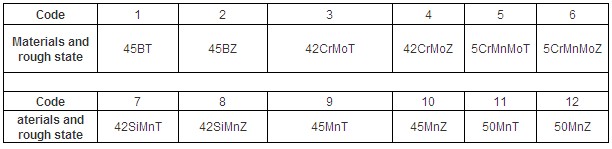

The ring material and the code of supply state of blanks will follow the stipulations in the table. In the table, Tindicates that the ring blank is supplied at the state of quenching and tempering;Zindicates that the ring blank is supplied at the state of normalizing.

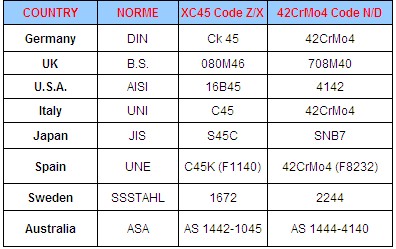

The diameter of central circle of rolling element 3150mm, ball diameter 75mm, gear modulus m=20mm, ring material 50Mn, blank material at the state of normalizing, the internal gear four-point contact ball slewing ring, it may be expressed as 013.75.3150.12.The following table shows our standard steelswith the nearest equivalent foreign grades.

Pages:1 1 Page