Causes of slewing bearing damage and countermeasur

1.Damage to the phenomenon of a slewing bearing

In the truck crane, excavators and other construction machinery, the slewing ring is a transmission between the turntable and the chassis of the axial load, radial load and tipping moment of the important parts.

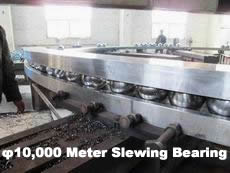

In light load condition when it can work, free to rotate. However, in heavy-duty, especially when the weight of the largest and most significant effect, the heavy rotation difficult, if not turn a result, the death card. Usually taken to reduce the rate at this time, adjusting the outrigger position or move the chassis so that the body tilt and other methods to help achieve the rotary movement of heavy weights, lifting, such as the completion of the scheduled operation. So often in the repair work will find slewing bearing raceway has been seriously damaged, with the seat in front of both sides and under the operation area Raceway Raceway have a direction along the circular crack, Office Block, circle the biggest force Raceway sag region and sag in the District have a radial crack, the damage to the state as shown in Figure

1. Ring within 2 blocks. Block 3 outside the circle. Roller

Figure 1 damaged state diagram Raceway

2 Causes of damage slewing bearing

(1) the impact factor of safety Zh

Slewing bearing often large load conditions in the low-speed operation, the carrying capacity of the general static capacity can be said that the rated capacity of static recorded as C0 a. Capacity refers to the so-called static Raceway achieve permanent deformation δ 3d0 / 10 000 when the carrying capacity of slewing ring, d0 for the rolling diameter. A combination of external load is generally used to indicate equivalent loading Cd. Equivalent static load capacity and safety factor as the ratio recorded for the fs, it is the design and selection of the main basis for slewing ring.

When checking between roller and raceway contact stress method of maximum slewing bearing design, the access line allowable contact stress σk 〔〕 line = 2.0 ~ 2.5 × 102 kN / cm. At present, most manufacturers are based on the size of external load on the calculation of slewing ring for selection. According to available information, currently small compared to the tonnage crane slewing bearing slewing crane large tonnage of the contact stress should be small, the actual safety factor higher. The greater the tonnage cranes, slewing ring diameter of its bigger, lower manufacturing precision, and its actually a lower safety factor, that is, large-tonnage cranes slewing cranes than small tonnage easier slewing the root causes of damage. Now widely recognized that, 40 t crane slewing above, the line of contact stress should not exceed 2.0 × 102 kN / cm, the safety factor should be not less than 1.10.

(2) the impact of structural stiffness Turntable

Turntable slewing ring is a transmission between the various load and chassis of the important parts, not its rigidity, and it relies mainly on supporting the chassis and the structural stiffness turntable. In theory, the ideal table structure for the cylindrical stiffness in order to allow table suffered uniformly distributed load, but it is not possible to machine the height restriction. On the turntable for the finite element analysis results show that the turntable slewing ring and connected to a larger deformation of the plate, the more serious side contains conditions, which focus on the role of load in the small portion of the roller, thereby increasing a single roller the pressure; the table is particularly serious deformation will change the structure of roller and raceway contact situation, greatly reducing the contact length and lead to a substantial increase in contact stress. At present, widely used and static contact stress calculation of capacity, are slewing force uniform and effective way to reach out roller roller length of 80% of the length of the premise. It is clear that this premise is not realistic. It is also easy to damage resulting in slewing another reason.

(3) the impact of treatment status

Slewing bearing itself by manufacturing quality precision machining, heat treatment of axial clearance and a great influence on the state, where the factor is easy to overlook the impact of heat-treatment state. Clearly, the raceway surface to crack and sag requires Raceway has sufficient surface hardness in addition to outside, we must also have sufficient depth of hardened layer and the core hardness. According to foreign data, the raceway depth of hardened layer should be increased with the rolling and thickening of the body, most more than 6 mm or more, the center should also be relatively high hardness, such Raceway will have a high capacity pressure ulcer. Therefore, slewing ring raceway surface hardened layer deep enough, the center of the low hardness, is also one of the reasons for its damage.

3, to improve the response

(1) through the finite element analysis, an appropriate increase Turntable slewing ring connected with the plate thickness of the site in order to improve the structural stiffness of the turntable.

(2) of large diameter slewing ring design should be appropriate to increase the safety factor; appropriate increase in the number of rollers can be improved roller and raceway contact situation.

(3) to improve manufacturing precision slewing ring, with a focus on the heat treatment process. IF quenching can reduce the speed to obtain greater surface hardness and hardening depth, surface raceway to prevent quenching cracks

For more information, kindly visit our website www.evon-engineering.com

Pages:1 1 Page